Turret Unwinds & Winders

Features:

- Rigid steel plate construction for 24/7 operation.

- Continuous unwinding for processes that cannot be stopped

- Pneumatic disc brakes

- Motorized turret indexing

- Serrated cut off knife using pneumatic actuation based on a footage preselect thru the PLC

- Pneumatically actuated bump roll working in conjuction with the flying knife to transfer the running web from the current roll to the new roll

- Dancer or load cell closed loop tension control

|

Products

|

|

|

|

|

|

|

|

|

Back

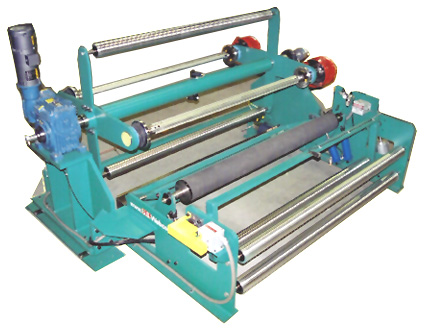

Shafted Turret Unwind Stand

|

|

Go to Conventional Turret Unwind Stand

|

|

The above shafted turret unwind was designed to unwind a plastic

masking film used in processing aluminum plate at the mill.

This unwind was designed to unwind web, splice and perform cut-off

from the top of the roll so that the adhesive side of the film

would be presented to the top of the sheet.

|

|

US Webcon offers a complete line of fully or semi automatic Shafted

Turret Center Unwinds and Rewinds to meet your production needs with

numerous features and options to fit your specific requirements The

US Webcon shafted turret unwind unit is designed to continuously unwind

rolls of paper, film and nonwoven product directly into the your process.

The web tension is automatically controlled using a pneumatically

operated dancer with feedback to a pneumatic brake for closed loop

control. A pneumatically operated bump roll and serrated knife assembly

performs cut-off and transfer of the new roll on the fly.

Options:

- Under or over unwind operation

- Surface driver to match line speed for higher speeds

- Magpartical brakes for tension sensitive webs

- Shafted of Shaftless operation

- Phantom shafted styles available

- Removeable mandrel or cantilevered designs where applicable

- Automatic edge guiding or manual positioning

- Driven unwinds are supplied with AC or DC Drives

- Optional Touch Screens

- Semi automatic or fully automatic operation

- Center or surface center winding.

- Standard or phantom shafted design

- Closed loop load cell or dancer tension control

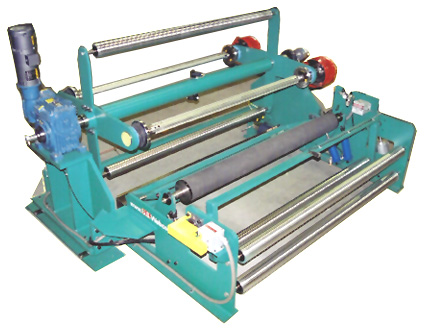

Conventional Shafted Turret Unwind Stand

|

|

The above shafted turret unwind was designed to unwind a kraft

paper liner used as an interleaf in rolled aluminum sheet metal

to prevent scratches on the painted surfaces. This unwind was

designed to unwind web in the conventional direction, splice and

perform cut-off for continuous unwinding. This unwind was guided

using a side laying electro-mechanical system.

|

Related Products:

Back

|