The Laminators

Features:

- Bi-Laminate capable

- High capacity brass insert type burner

- Gas premixer for variable flame adjustment

- Bowed roll to spread the web

- Water cooled rolls

- Digital nip gap read out

- AC vector motors and drives

|

Products

|

|

|

|

|

| |

|

|

Back

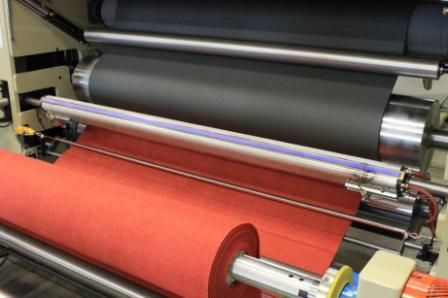

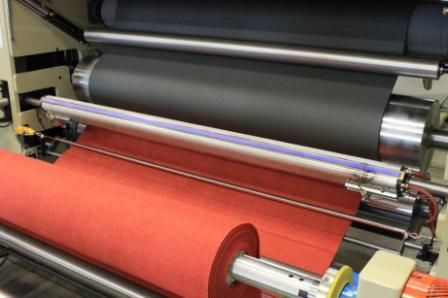

Bi Laminate Flame/Foam Laminator

The above laminator is a Single Burner Two Roll Flame Laminator designed to laminate two webs to fabricate a 2 ply bi-lamination at a common nip point consisting of foams and fabrics or vinyl goods on a roll to roll basis. |

Machinery Included:

- Overhead Foam Unwind

- Floor Mounted Unwind for Vinyl

- Single Burner Flame Laminator Head

- A-Frame Center Winder

|

US Webcon offers a complete line of Flame Laminating Equipment and machinery to meet your production needs with numerous features and options to fit your specific requirements. This heavy duty Flame laminator is designed to laminate one web material to another by impinging a gas flame against one surface to either melt or change state. This creates an adhesive that will bond the two webs together making a 2 ply construction when passed through a common nip point. |

The above picture shows the elevated foam unwind that feeds foam into the flame laminator to fabricate a 2 Ply foam bi-lamination. A hydraulic driven A-frame winder center winds the finished laminate. |

Possible Laminations:

- Polyurethanes to Fabric

- Polyurethanes to Vinyl

- Polyethylene Foam to Foam to build up thickness

- Polypropylene foam to foam

- Geonet to Geotextiles

|

Industries Served:

- Sports and Gymnastics

- Automotive Seating

- Automotive Head Liner

- Military

- Garments

- Insulation

|

The above picture shows the burner after flame ignition in the home position ready to initiate burner roll over and the start of laminating. |

The above picture shows the burner rolled over in the lamination position melting the surface of the foam just prior to being laminated to a carpet material as it passes through the laminator nips. |

Options:

- Web handling for continuous operation

- Accumulators

- Recipe systems

- Infeed systems with edge guiding and foam tension control

- Full pollution control system

- Impulse Butt Splicer for foam

Related Products:

|

US Webcon can modify the above design to meet your specific needs and requirements. Call us to discuss your application with one of our engineers at (570) 644-1401.

Back

|